Gears¶

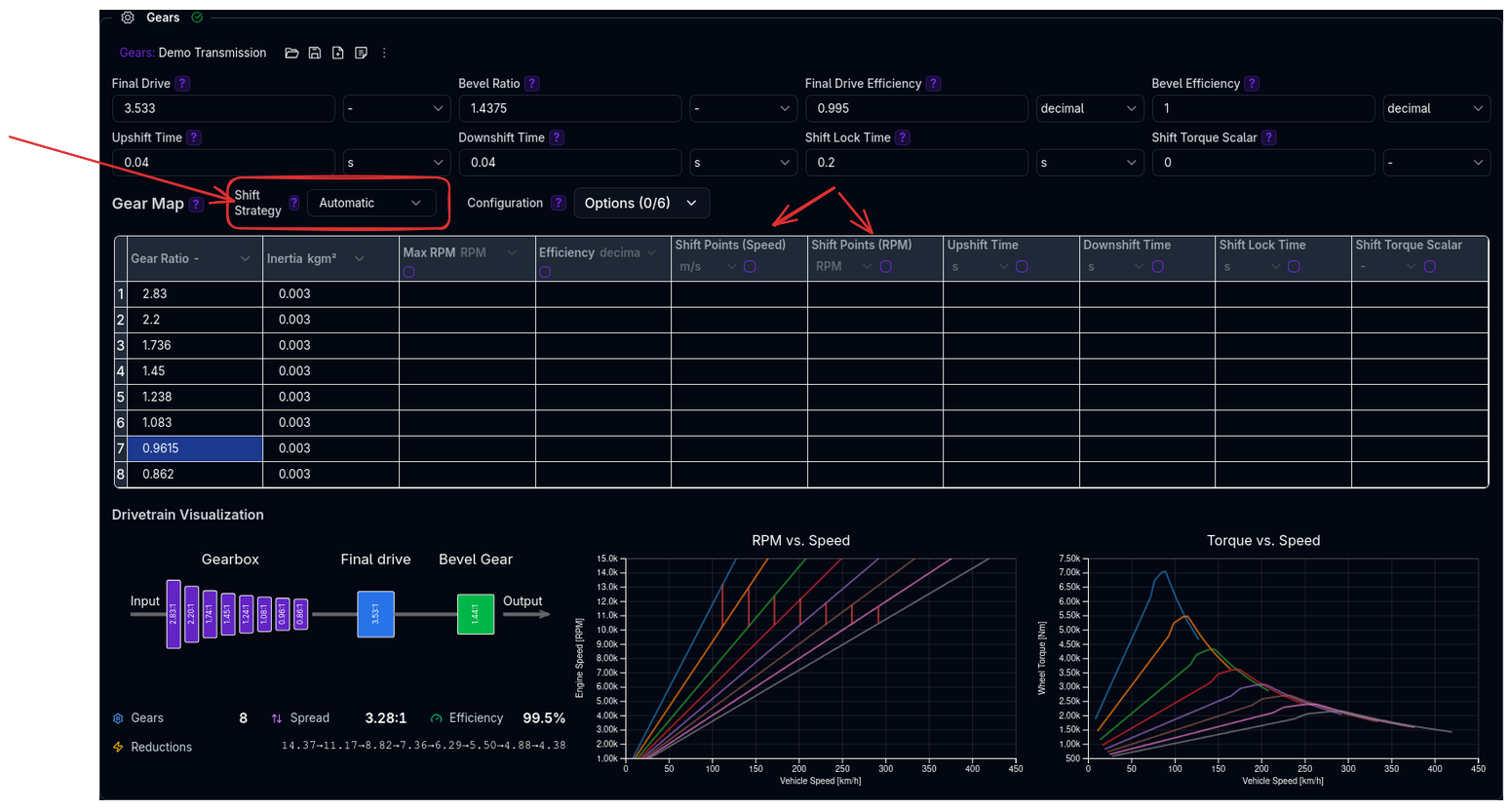

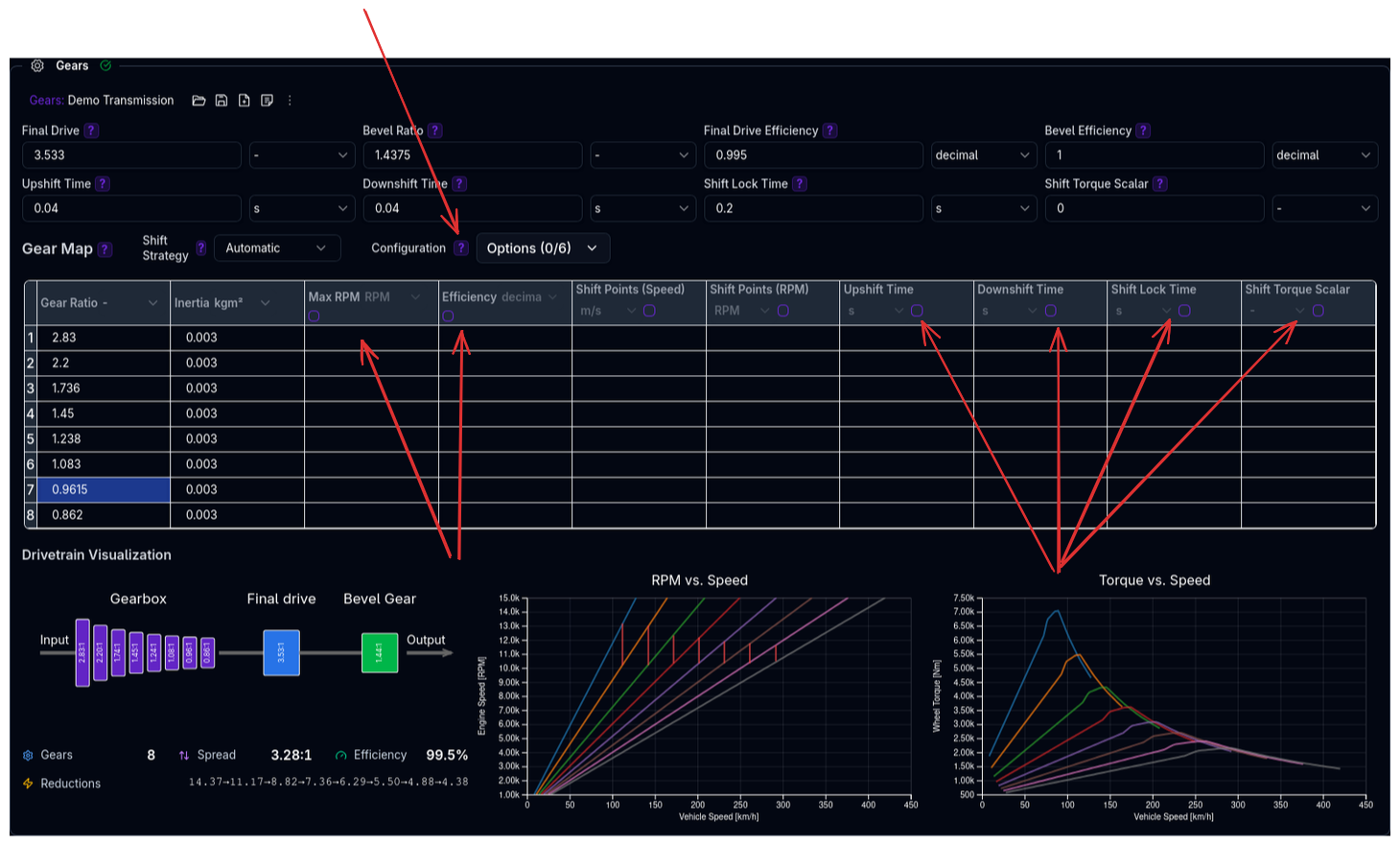

Configure gear ratios, shift timing, shift strategy, and transmission properties for optimal power delivery.

The Gears component is an independent library component — it can be saved, loaded, duplicated, and shared separately from the parent Powertrain.

Parameters¶

Core Transmission Settings¶

| Parameter | Description | Unit |

|---|---|---|

| Final Drive | Gear ratio between gearbox and wheels | - |

| Bevel Ratio | Ratio of bevel gears in drivetrain | - |

| Final Drive Efficiency | Efficiency of final drive component | decimal (0–1) |

| Bevel Efficiency | Efficiency of bevel gear component | decimal (0–1) |

Drivetrain Ratios

- Final Drive affects overall torque multiplication and top speed

- Bevel Ratio is typically used for drivetrains with angle changes in the driveline

Gear Map Configuration¶

The gear map defines ratios and optional parameters for each gear:

| Parameter | Description | Unit |

|---|---|---|

| Gear Ratio | Torque multiplication for each gear | - |

| Inertia | Rotational inertia of each gear assembly | kg·m² |

| Max RPM | Maximum RPM limit per gear (optional) | RPM |

| Efficiency | Transmission efficiency per gear (optional) | decimal (0–1) |

Shift Timing Parameters¶

| Parameter | Description | Unit |

|---|---|---|

| Upshift Time | Time to complete an upshift | s |

| Downshift Time | Time to complete a downshift | s |

| Shift Lock Time | Minimum time between gear changes — prevents rapid gear cycling | s |

All shift timing defaults to 0.0 s and can be set globally or per gear.

Torque Management¶

| Parameter | Description | Unit |

|---|---|---|

| Shift Torque Scalar | Torque multiplier applied during gear changes | decimal (0–1) |

Shift Torque Scalar

- 0.0: Complete torque cut during shifts (smoothest)

- 0.5: 50% torque maintained (balanced)

- 1.0: No torque reduction (harshest shifts)

Shift Strategy¶

Controls how and when gears are changed:

| Strategy | Description |

|---|---|

| Automatic | Computer-controlled optimal shifting |

| Manual Speed | User-defined shift points by vehicle speed (m/s) |

| Manual RPM | User-defined shift points by engine/motor RPM |

For manual strategies, you must define N−1 shift points for N gears (e.g., 5 gears = 4 shift points).

Configuration Options¶

Enable advanced per-gear settings through the Configuration dropdown:

| Option | Description |

|---|---|

| Specify max RPM per gear | Set individual RPM limits per gear |

| Specify transmission efficiency | Different efficiency per gear |

| Specify upshift time per gear | Individual upshift durations |

| Specify downshift time per gear | Individual downshift durations |

| Specify shift lock time per gear | Individual lock times per gear |

| Specify shift torque scalar per gear | Different torque reduction per gear |

Validation Warnings¶

Gear Ratio Warnings¶

| Condition | Warning |

|---|---|

| No gear ratios defined | At least one gear ratio must be defined |

| Uneven ratio progression (coefficient of variation > 20%) | Uneven gear ratio progression may affect driving experience |

| Ratio step between consecutive gears > 2.0 | Large gear ratio step may cause significant RPM drops during shifts |

| First gear ratio < 2.0 | First gear ratio might be too tall for good acceleration |

| First gear ratio > 5.0 | First gear ratio might be too short for smooth starts |

| Gear ratio spread < 2.0 | Small gear ratio spread — consider wider spacing |

| Gear ratio spread > 8.0 | Large gear ratio spread — may be unrealistic |

Drivetrain Warnings¶

| Condition | Warning |

|---|---|

| Final drive < 2.5 | Low final drive ratio may limit acceleration |

| Final drive > 5.0 | High final drive ratio may limit top speed |

| Transmission efficiency < 0.85 (any gear) | Low transmission efficiency for gear X |

| Bevel efficiency < 0.85 | Low bevel gear efficiency may impact performance |

| Final drive efficiency < 0.85 | Low final drive efficiency may impact performance |

Shift Timing Warnings¶

| Condition | Warning |

|---|---|

| Upshift time > 0.5 s (any gear) | High upshift time for gear X |

| Downshift time > 0.5 s (any gear) | High downshift time for gear X |

Tips¶

- Progressive Ratios: Ensure smooth acceleration through all gears with even ratio steps

- Appropriate Final Drive: Balance acceleration and top speed for your application

- Realistic Shift Times: Match shift timing to your transmission type (manual, sequential, DCT, etc.)

- Efficiency Values: Use manufacturer data when available; leave at default (1.0) otherwise

Next Steps¶

- Configure Differential for torque distribution behaviour

- Set up Efficiency for detailed powertrain losses

- Configure power source (Engine or Electric Motor)

- Return to Powertrain Overview