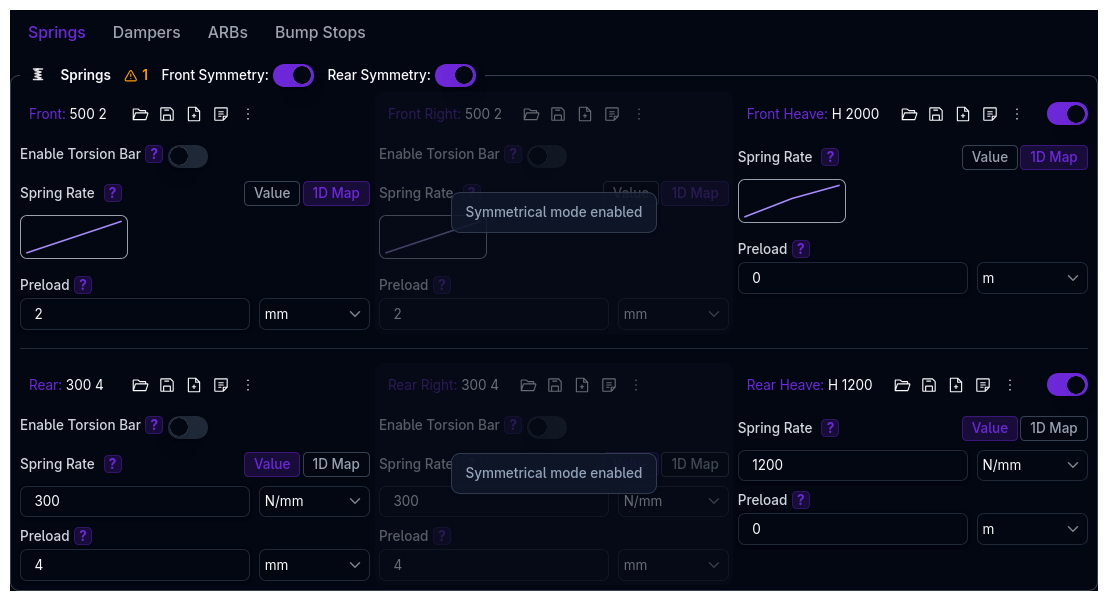

Springs¶

Configure corner springs and optional heave springs for each axle. Springs are the primary load-bearing element of the suspension and determine ride height, ride frequency, and weight transfer characteristics.

Each corner spring is an independent library component that can be saved, loaded, and shared separately.

Spring Types¶

Two spring types are available for corner springs. The type is determined by the actuation configuration in Kinematics.

Linear Spring¶

The default spring type. Operates in the linear (translational) domain, producing a force proportional to displacement.

| Parameter | Description | Unit |

|---|---|---|

| Spring Rate | Stiffness of the spring — constant value or 1D map (Distance vs Force) | N/m |

| Preload | Initial compression distance applied to the spring at rest | m |

The Spring Rate supports two data type modes:

- Value — a single constant spring rate

- 1D Map — a lookup table of displacement (m) vs force (N) for progressive or degressive springs

Torsion Bar¶

A torsion bar operates in the angular (rotational) domain, producing a torque proportional to rocker angle. Torsion bars are only available when the actuation type is set to push/pull rod with rocker in Kinematics. When actuation is set to direct-acting, the torsion bar option is disabled.

| Parameter | Description | Unit |

|---|---|---|

| Torsion Stiffness | Rotational stiffness — constant value or 1D map (Angle vs Torque) | Nm/rad |

| Preload Angle | Initial angular preload applied to the torsion bar | rad |

The Torsion Stiffness supports two data type modes:

- Value — a single constant torsional stiffness

- 1D Map — a lookup table of angle (rad) vs torque (Nm)

When to Use Torsion Bars

Torsion bars are common in Formula-style cars with rocker-actuated suspension. If your suspension is direct-acting (e.g., most production cars, GT cars), use linear springs.

Motion Ratios and Effective Rates¶

Spring parameters are entered at the component level (i.e., the physical spring itself). The motion ratio from Kinematics converts between component-level values and wheel-level values.

Linear Spring Motion Ratio¶

The spring motion ratio is the ratio between how much the spring moves relative to how far the wheel moves:

Motion Ratio = Spring Travel / Wheel Travel

It is a unitless value, typically less than 1. A higher motion ratio means the spring moves more for a given amount of wheel travel, making the suspension effectively stiffer. The effective wheel rate is:

Torsion Bar Motion Ratio¶

For torsion bars, the motion ratio is the ratio between the rocker angle and the wheel travel:

Motion Ratio = Rocker Angle (rad) / Wheel Travel (m)

This has units of rad/m. A higher motion ratio means the torsion bar twists more for a given amount of wheel travel, making the suspension effectively stiffer. The effective wheel rate is:

Motion ratios are read-only

Motion ratios are not entered on the Springs page — they are calculated from the suspension geometry defined in Kinematics. The Suspension Metrics panel shows the current motion ratios and resulting wheel rates.

Heave Springs¶

Heave springs are optional and toggled independently per axle. When enabled, a heave spring acts on the average wheel displacement of the axle, providing additional vertical stiffness without affecting roll stiffness.

Heave springs are always linear springs:

| Parameter | Description | Unit |

|---|---|---|

| Spring Rate | Heave spring stiffness — constant value or 1D map | N/m |

| Preload | Initial compression distance | m |

Heave Springs

Heave springs allow you to decouple ride stiffness from roll stiffness. A softer corner spring with a heave spring can give the same ride rate but lower roll stiffness than a stiff corner spring alone.

Validation Warnings¶

Linear Spring¶

| Condition | Warning |

|---|---|

| Preload distance > 10 mm | High preload |

| Preload distance > 20 mm | Extremely high preload |

| Preload distance < 0 | Negative preload |

| Linearized spring rate < 10 N/mm | Low spring rate |

| Linearized spring rate > 600 N/mm | High spring rate |

Torsion Bar¶

| Condition | Warning |

|---|---|

| Preload angle > 5° | High preload angle |

| Preload angle > 10° | Extremely high preload angle |

| Preload angle < 0 | Negative preload angle |

| Linearized torsion stiffness < 1,000 Nm/rad | Low torsion stiffness |

| Linearized torsion stiffness > 100,000 Nm/rad | High torsion stiffness |

Heave Spring¶

| Condition | Warning |

|---|---|

| Heave spring rate < 100 N/mm | Very soft heave spring |

| Heave spring rate > 5,000 N/mm | Very stiff heave spring |

Related Pages¶

- Suspension Overview — Component hierarchy and page layout

- Dampers — Damping configuration

- Kinematics — Actuation type and motion ratios

- Data Types — Value vs 1D Map modes